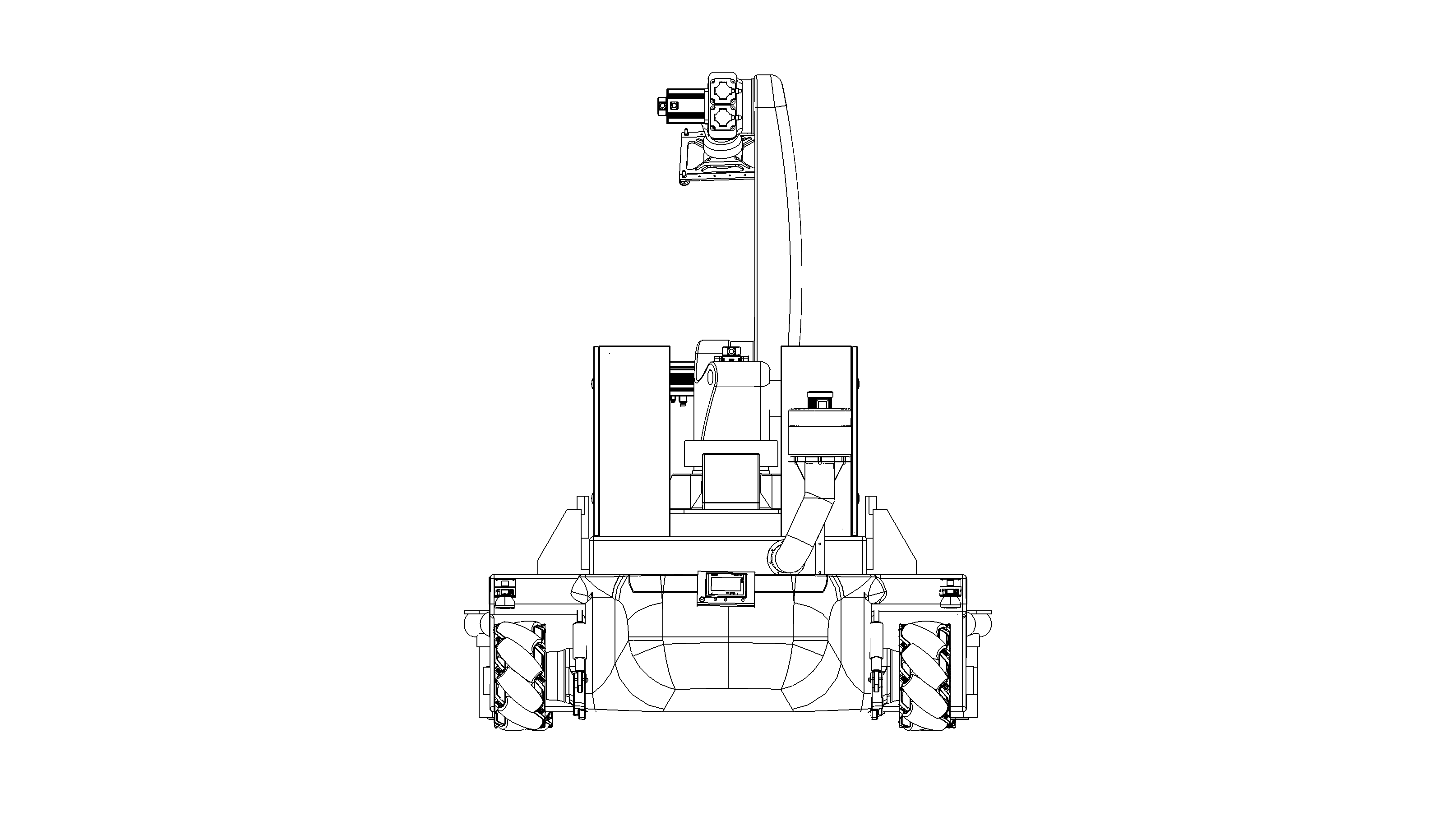

A New Trend in Large Component Manufacturing

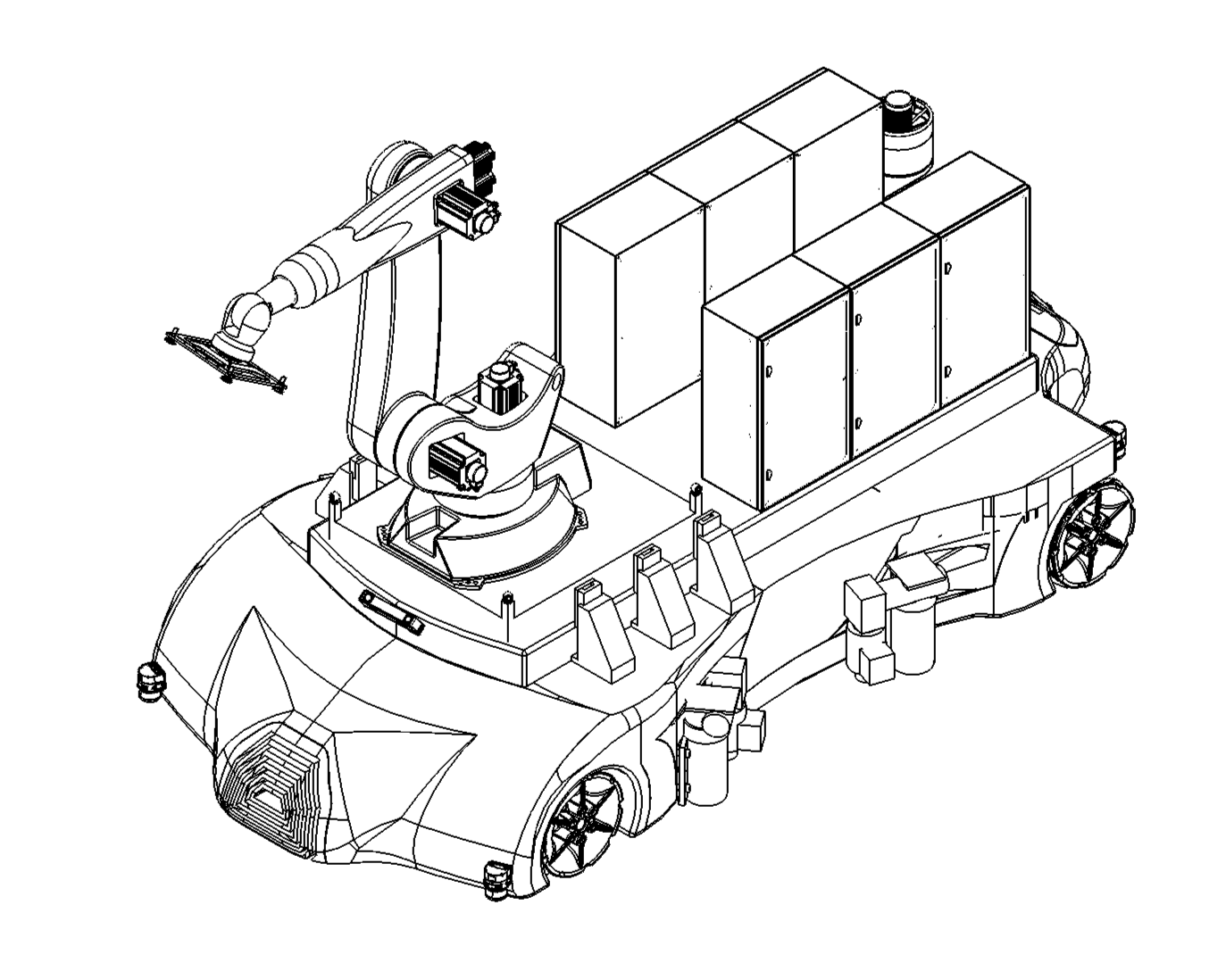

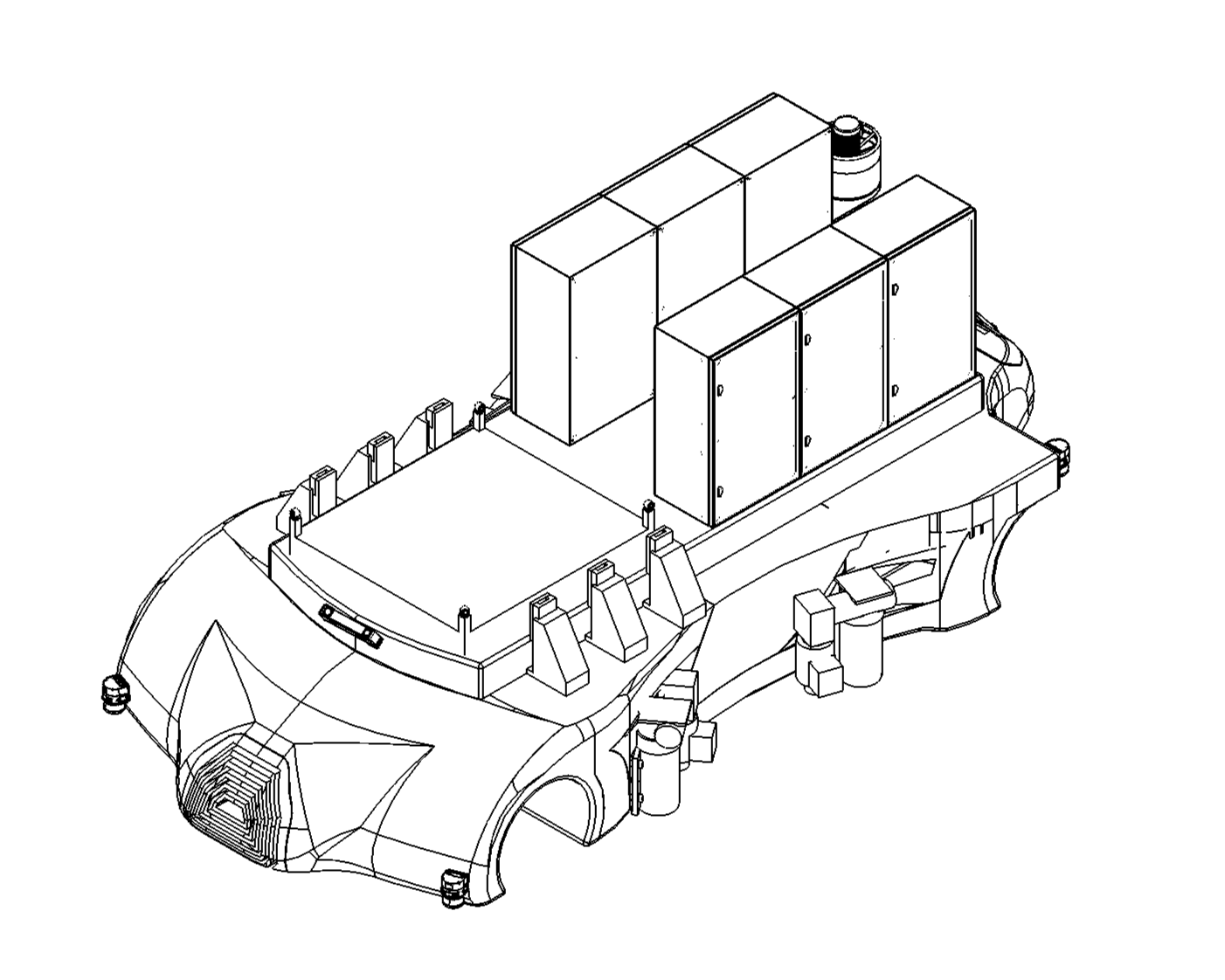

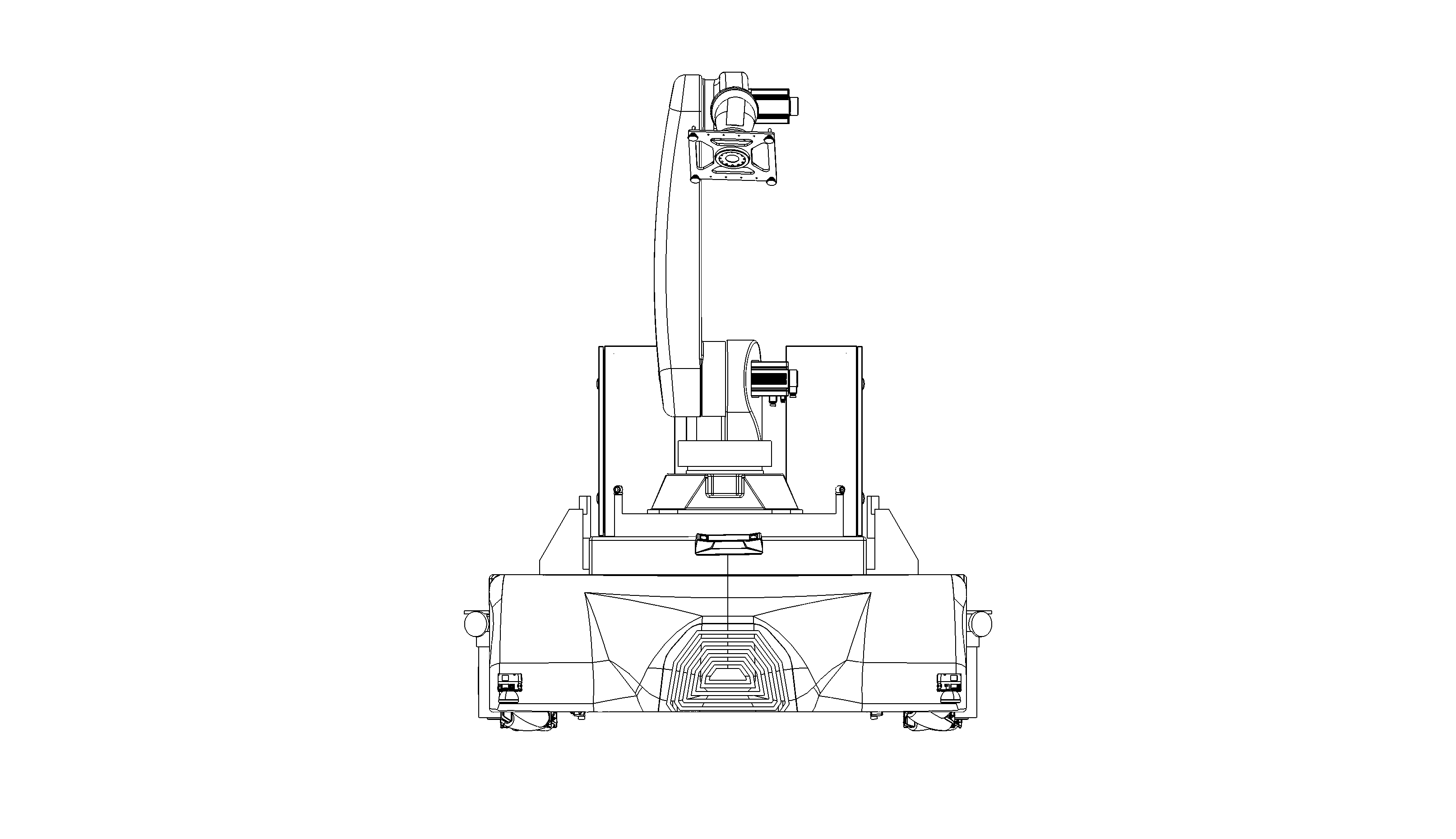

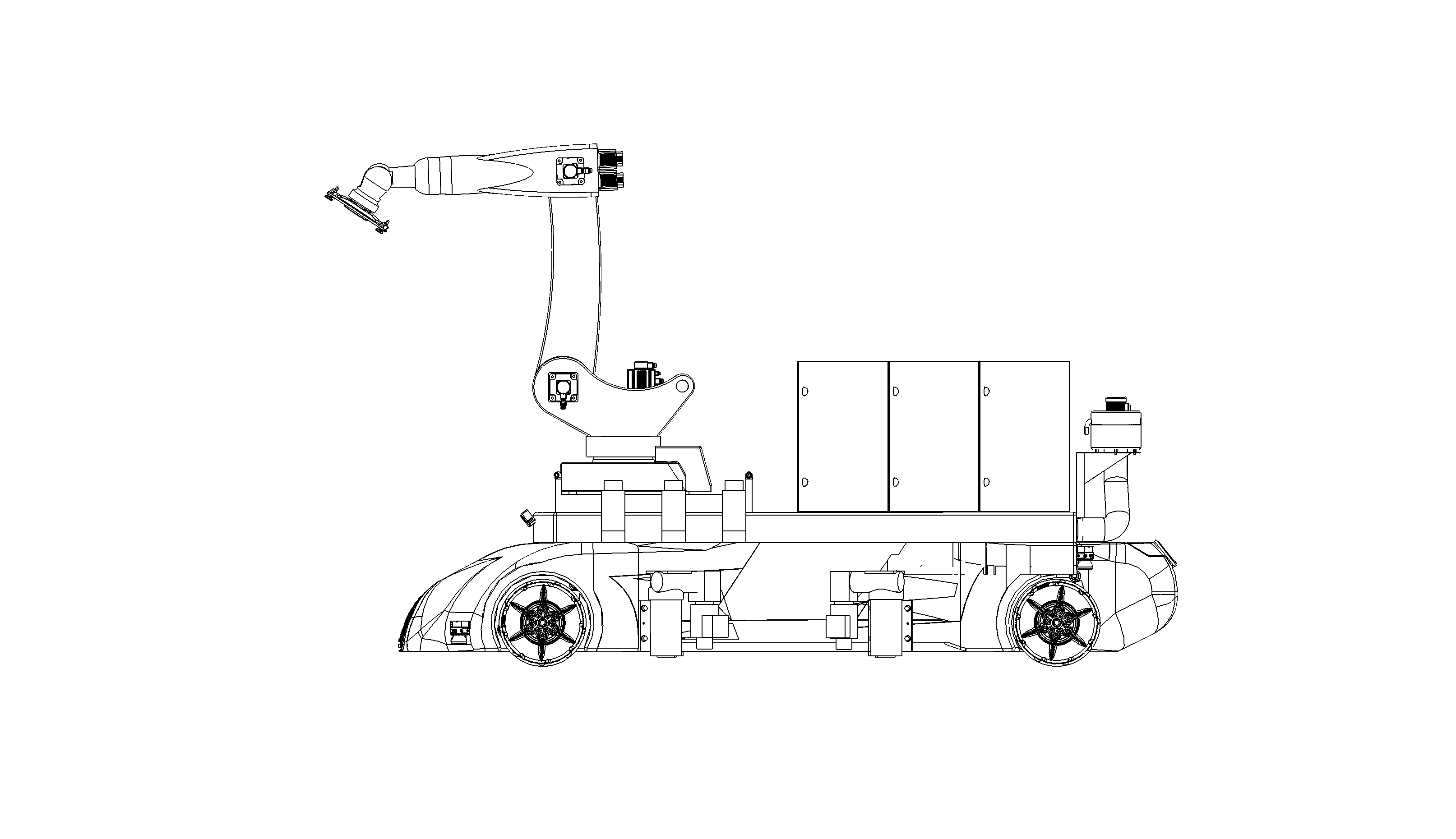

The need to manufacture large parts in stringent requirements is growing across many industries, and traditional production solutions are often inflexible, with generally high production costs and cycle times. Large, heavy shop-level machines and equipment are often used, resulting in high manufacturing costs. The large, specialized equipment is limited in terms of versatility. In order to meet the demand for shorter development cycles, lower costs and higher efficiency for large workpieces, there is an urgent need for multifunctional systems that can continuously adapt to technological advances.